As we talk about strainers, this might be a good time to review the general purpose of a strainer. A strainer is used to “strain” or “filter” contaminates in a piping system that could flow down the pipeline and damage more expensive pieces of equipment, or spoil a manufacturing process. In effect, a strainer could be viewed as a very inexpensive “insurance policy” to help protect the overall piping systems. Strainers are available in many materials, types, and end connections. These various options are designed to help the end user obtain the best possible straining device for their specific applications.

Strainers can be obtained in threaded ends, socket weld, butt weld and flanged ends. Higher pressures are also available in other special end connections. Body materials can range from iron, carbon steel, stainless steel, bronze and many special alloys. Some manufacturers even offer FRP units (fiberglass reinforced plastic) bodies, for significant corrosion resistance, at a lower cost and with a greatly reduced installed weight.

The selection of the straining element (screen or basket) is typically based on the line media (what’s going through the pipeline). The term “screen” is typically used in wye strainers, while “basket” is the term that is used in a basket type strainer. The internals of a strainer are really the internal screening, or filtering element. Additional factors include what may be flowing through the line, and the degree of straining that the customer has determined needs to take place. Pressure drops, line pressure, flow rate are just a few of the considerations that may be factored in. For more information regarding the selection of straining elements, see the blog post “Choosing the Right Straining Element“.

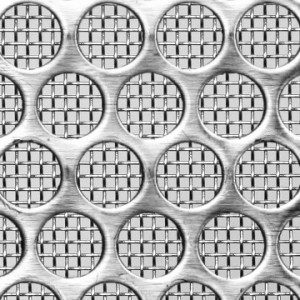

The straining elements are generally made from a wire mesh type screen material or a perforation in sheet metal. In some cases, depending on size and pressure rating, a mesh unit may additionally include a perforation. Using a perforated material in conjunction with a mesh, may be best in providing greater strength and stability to the straining element.